At Jalaram Engimech is the ISO 9001: 2015 Company understand that a high-quality deliverable is possible only when excellence is upheld at every stage of the process.

To this effect, we buy only the finest quality of raw materials to Manufacture All processing is then carried out at our state-of-the-art manufacturing unit under the supervision of an adroit team of professionals inclusive of engineers, technocrats, and other skilled workers.

With multiple quality checks placed at every step of the manufacturing process, we ensure that only the highest quality industrial Components of international standards reaches our dedicated packing unit.

Here, it is handled and packed with care, so that it is ready to be delivered anywhere around the world in the same pristine condition that it has been manufactured.

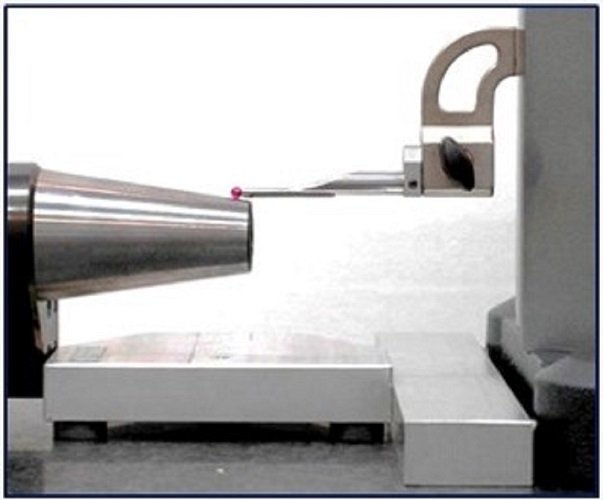

Testing and Inspection Facilities List

| Sr No | Description of Equipment | Make | Qty |

|---|---|---|---|

| 1 | 2D Height Gauge | Trimos - Switzerland | 1 |

| 2 | Height Gauge | Mitutoyo - Japan | 1 |

| 3 | Surface Roughness Tester | Mitutoyo - Japan | 1 |

| 4 | V- Block magnetic | Sagar | 6 |

| 5 | Universal Hardness Tester | Noble | 1 |

| 6 | Slip Gauge Box | Mitutoyo | 1 |

| 7 | Magna Flux | Vinze Magnafield Controls Pvt. Ltd. | 1 |

| 8 | Vision Inspection system | Sipcon | 2 |

| 9 | Weighting Scale | Sensita | 1 |

| 10 | All Necessary Instruments required for Dimensional Inspection Viz. Vernier Calipers, Micrometers, Height Gauges, Ring Gauge, Dial Indicators, Bore Gauge, snap gauges, Thread Ring & Plug Gauges, etc. | Mitutoyo, Baker & Advance |

Quality Assurance Plan

| Sr No | Activity Description | Reference Documents | Acceptance Criteria | Format of Record | Performer |

|---|---|---|---|---|---|

| 1 | RAW MATERIAL INSPECTION AND TESTING | ||||

| 1.1 | Chemical Inspection | chemical sheet | As per Chart | Chemical TC | Test Lab. |

| 1.2 | Hardness Test | Grade Chart | As per Required | Raw Material Inspection Report | QCI |

| 1.3 | Crack Detection | -- | No Crack | ||

| 2 | MANUFACTURING PROCESS CONTROL | ||||

| 2.1 | Forging | Forging Drawing | Forging Drawing | Inspection Report | QCI |

| 2.2 | Cutting / Machining Process | Machining Drawing | Machining Drawing | Operator | |

| 2.3 | Threading | Finish Drawing. | As per Gauges | ||

| 2.4 | Heat Treatment | Grade Char | As per Required | Hardness TC | QCI |

| 2.5 | Grinding | Finish Drawing | Finish Drawing | Inspection Report | QCI |

| 2.6 | Chemical Inspection | Finish Drawing | Finish Drawing | Inspection Report | QCI |

| 3 | INSPECTION & TESTING | ||||

| 3.1 | Final Inspection | Finish Drawing | Finish Drawing | Inspection Report | QCI |

| 4 | PACKING & DISPATCH | ||||

| 4.1 | Packing | Work Instruction | P.O. | Packing Slip / Tag. | Store In charge |

| 4.2 | Pre-dispatch Inspection | Finish Drawing | Finish Drawing | Pre-dispatch Inspection Report | QCE |

| 4.3 | Dispatch | P.O. | -- | DC / Invoice / GR | Dispatch In charge |